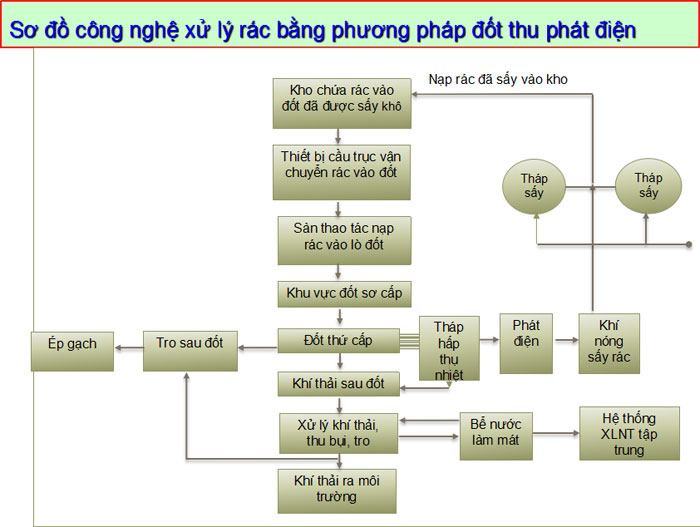

The technology burns heat, converts it into electricity, and simultaneously generates heat for the desiccant drying in the waste treatment line.

Burning of individual garbage is a type of organic waste that is difficult to decay in the process of separating filtering of individual garbage (straw, grass, branches, rags, blankets, mosquito nets, wooden toys and stuffed animals etc.) with a mix of 5-10% synthetic rubber waste and synthetic polymers.

Spinning organic fibers is a slow-growing organic substance, which occurs during the separation process of raw organic humus.

Group 2 organic waste is a large, long, large, tough, hard-to-decomposed organic matter that is present in the waste sorting process.

The furnace is reasonably designed combustion cycle. Primary fire, separate secondary fire, the oven must be absolutely sealed not to leak out of the area of the furnace operator.

Garbage is automatically disposed to burn garbage, including ash removed from the oven is also automated.

The heat of the secondary combustion chamber must not be less than 9000C and the room temperature is not less than 10000C.

Heat recovery converts into turbocharged gas turbine power generators and drying waste for fuel.

Incinerator smoke is thoroughly treated according to environmental protection standards

The furnace is fully mechanized, partly automated

There are effective measures to limit heat dissipation to protect the health of the furnace workers and adjacent areas of the furnace

Utilize heat to dry and reduce moisture